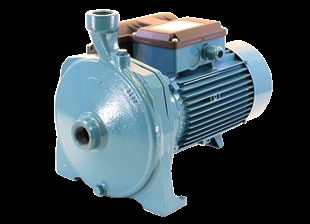

- For clean liquids without abrasives, which are, non aggressive for the pump materials ( solids content up to 0.2%).

- For water supply.

- For heating, air-conditioning, cooling and circulation plants.

- For civil and industrial applications.

- For irrigation.

Pearl - Centrifugal

The compact design allows for easy installation even in confined spaces. The mechanical structure of the hydraulic parts in contact with the pumped liquid are dimensioned to guarantee the maximum resistence to mechanical stress.

The lantern bracket design prevents contact with the pumps rotating parts, providing protection to the end user whilst allowing for inspection of the mechanical seal.

The bearing and shaft are designed to ensure the reduction of the stress, providing high reliability under all operating conditions.

TWO BACK-TO-BACK IMPELLER

The option to choose between cast iron and bronze materias for the hydraulic parts in contact with the pumped liquid allows two back-toback impellers series pumps to be selected for use with different types of liquids.

The mechanical structure of the hydraulic parts in contact with the pumped liquid are dimensioned to guarantee the maximum resistence to mechanical stress.

The bearing and shaft are designed to ensure the reduction of the stress, providing high reliability under all operating conditions.

Descripción del producto

The compact design allows for easy installation even in confined spaces. The mechanical structure of the hydraulic parts in contact with the pumped liquid are dimensioned to guarantee the maximum resistence to mechanical stress.

The lantern bracket design prevents contact with the pumps rotating parts, providing protection to the end user whilst allowing for inspection of the mechanical seal.

The bearing and shaft are designed to ensure the reduction of the stress, providing high reliability under all operating conditions.

TWO BACK-TO-BACK IMPELLER

The option to choose between cast iron and bronze materias for the hydraulic parts in contact with the pumped liquid allows two back-toback impellers series pumps to be selected for use with different types of liquids.

The mechanical structure of the hydraulic parts in contact with the pumped liquid are dimensioned to guarantee the maximum resistence to mechanical stress.

The bearing and shaft are designed to ensure the reduction of the stress, providing high reliability under all operating conditions.

- Liquid temperature from 14 °F to 194 °F.

- Ambient temperature up to 104 °F.

- Total suction lift up to 23 ft.

- Maximum permissible working pressure up to 145 psi (232 psi

for pumps NMD 25/190). - Continuous duty.

- Close-coupled, centrifugal pumps; electric motor with extended shaft directly connected to the pump.

- Single-impeller

- Two back-to-back impellers (with axial thrust balancing).

- Connections: threaded ports NPT.

- Other voltages.

- Special mechanical seal.

- Higher or lower liquid or ambient temperatures.