- Suction Size: 1 1/4? to 4? ANSI

- Discharge Size: 1 1/4? to 4? ANSI

- Range of HP: 1/2 to 50 HP

- Capacity: 3 to 390 GPM

- Head: 24 to 930 Ft.

- Working pressure: 360 PSI (25 Bar) max. (please refer to the technical section for specific pressure information)

- Temperature: -22 ? to +248 ?F (-30 ? to 120 ?C)

- Liquid: clean water, hot water

EVMSU/EVMSUL

EBARA’s Model EVMSU vertical multistage pump features a newly designed “Shurricane™” impeller that reduces the axial thrust load with higher pump efficiency created by the innovative hydraulic design of the impeller shrouds. The Shurricane™ impeller is designed to deliver optimum hydraulic efficiency and significantly reduce axial thrust loads so that standard C face motors may be used with no special (thrust) bearing requirements. The EVMSU also features cartridge type mechanical seals (single inside unbalanced or balanced as required). To allow for mechanical seal replacement without removal of the motor, a spacer coupling is provided on units with motor horsepower of 7-1/2 and above.

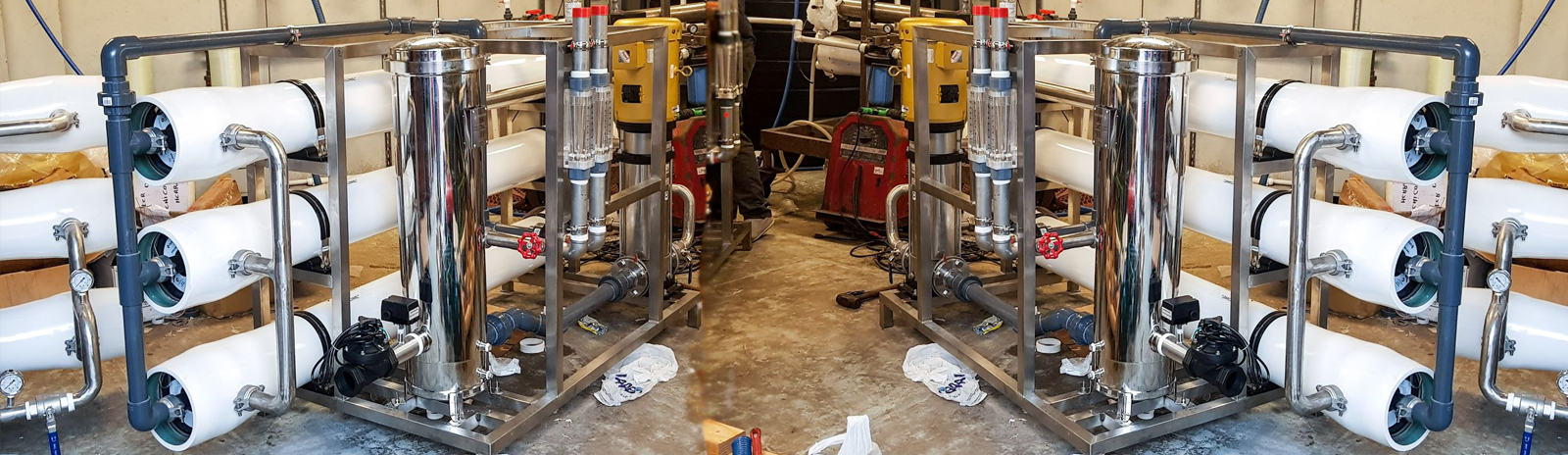

With hydraulic coverage to 390 GPM and 930 feet TDH, the EBARA model EVMSU is designed for booster, water purification, and hot water applications.

Descripción del producto

EBARA’s Model EVMSU vertical multistage pump features a newly designed “Shurricane™” impeller that reduces the axial thrust load with higher pump efficiency created by the innovative hydraulic design of the impeller shrouds. The Shurricane™ impeller is designed to deliver optimum hydraulic efficiency and significantly reduce axial thrust loads so that standard C face motors may be used with no special (thrust) bearing requirements. The EVMSU also features cartridge type mechanical seals (single inside unbalanced or balanced as required). To allow for mechanical seal replacement without removal of the motor, a spacer coupling is provided on units with motor horsepower of 7-1/2 and above.

With hydraulic coverage to 390 GPM and 930 feet TDH, the EBARA model EVMSU is designed for booster, water purification, and hot water applications.

- Municipal

- Industrial

- Agriculture

- Pressure/water boosting

- Boiler feed

- HVAC

- Hot/Cold water circulation

- Fire fighting

- Filtration

- Reverse osmosis

- Washing systems

- Filtration

- Irrigation

- Standard NEMA motor sizes

- Low axial thrust impeller enables long motor bearing life

- Air vent in casing cover allows proper venting preventing air entrapment and dry run

- Fill port in casing cover allows for water fill, as well as installation of sensors, gauges, and other measuring devices

- Liner ring is a self-aligning, floating design constructed to prevent swelling at high temperatures

- Tungsten carbide lower pump bearings and sleeves are standard construction for all services, providing maximum operating life

- Direct drive pump and motor shafts are keyed for positive, reliable power transmission with no adjustments necessary

- “Flexible” floating outer casing allows for thermal expansion in hot water applications, preventing deformation due to pressure fluctuations

- Square-edge four spline shaft provides positive location and drive of impellers, eliminating wear

- Dimensions & flanges – installation is to market accepted dimensions for easy upgrade of existing installations

- Piping connection options include Fixed ANSI compatible flange, Oval flange, Loose ANSI compatible flange, victaulic, and clamp connections

- Mechanical seal – Silicon Carbide/Carbon/Viton mechanical shaft seal. Cartridge mechanical seal design enables replacement without disassembling the motor bracket